EQUIPMENT

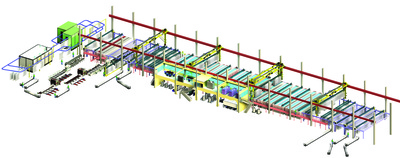

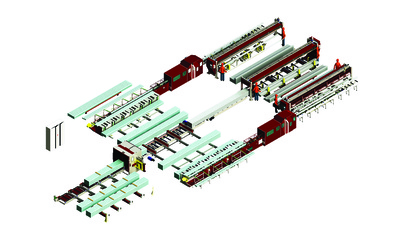

Our engineering team at GRANCO CLARK takes pride in utilizing cutting-edge technology to design and develop custom equipment that meet the needs of clients worldwide.

One of the key elements that sets us apart from our competitors is our use of the most advanced programs available. Our engineers are experts in the use of the latest software and tools, which allows us to create highly precise and efficient equipment that meet the most demanding specifications.

At GRANCO CLARK, we understand that each project presents unique challenges and requirements. That’s why we take a customized approach to every project we undertake. We work closely with our clients to identify their needs and develop solutions that meet their specific requirements. Our team has extensive experience in the design and development of a wide range of custom equipment. We have the expertise and technology to handle projects of any size and complexity.

Log Processing

Granco Clark specializes in providing advanced log processing solutions through our custom-engineered equipment designed specifically for operations before the press.

Log ProcessingLog Processing

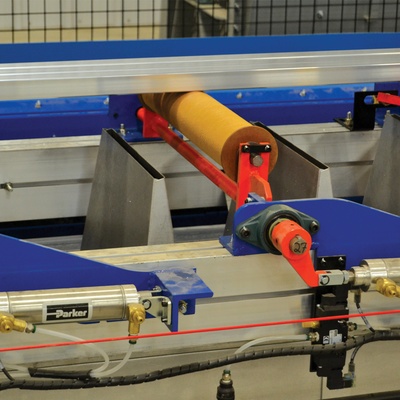

Log Table & Pusher

The GRANCO CLARK Billet and Log Table loads precut stock from the Table to the Pusher, dramatically improving cycle times. While a billet or log is being pushed into a GRANCO CLARK Furnace, the loading section of the conveyor will lower, allowing low-impact transfer from the table. Once the pusher head is in the “home” position, the load will be raised and the head will begin processing the new stock. When a new billet/log is loaded from the table in a lowered position, the roller bed will raise to allow the GRANCO CLARK Pusher to process the new billet/log.

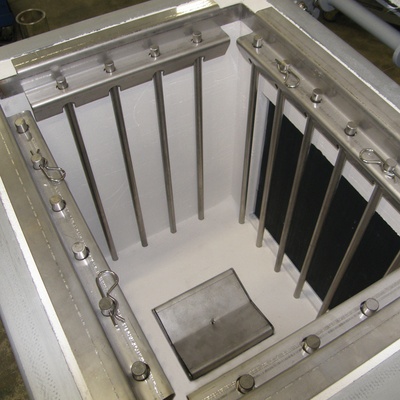

More InfoLog Washer

Improving the quality of logs for a superior extrusion begins with GRANCO CLARK's Log Washer. As logs pass through, they receive a high-pressure, 3000 psi water spray that removes contaminants. By doing this, it extends the life of your die and container, reducing maintenance. The GRANCO CLARK Log Washer is constructed of stainless steel, with sealed bearings and brushes on ends for water containment (no aluminum dust explosion hazard and no brush replacement). No electronics or electrical devices near the spray make this log washer superior to any other log washer on the market. (It has a simple, sleek design and can be added to an existing line with minimal effort).

More InfoHot-Jet Billet & Log Furnace

Hot-Jet Billet & Log Furnace GRANCO CLARK delivers the industry's most efficient flame-impingement Aluminum Log and Billet Furnace. After all, we invented the flame-impingement furnace, the tunnel furnace, and the jet preheat furnace well over 50 years ago. We set a new standard in the extrusion industry. That design has continued to evolve, most notably by the addition of an energy-saving “hot-jet” preheat section. It is still the fastest, most energy-efficient way to heat billets and logs. Hundreds of manufacturing plants worldwide have GRANCO CLARK furnaces; some are over 30 years old and still on the job. Flame-Impingement Furnace: One of the most energy-efficient furnaces available Hot-Jet preheat section Thermal efficiency up to 88% Improved Thermal Performance: New nozzle design …

More InfoHot Log Saw

Hot Log Saw The GRANCO CLARK Hot Billet Saw provides a major enhancement to consistent line throughput. Its servo-controlled physical stop allows the heated billets to be cut to the exact length needed before entering the press. A hot billet saw eliminates the need to maintain an expensive inventory of different-length billets. Billets are cut to the required size after heating. Hot-cutting also prevents the downstream problem of having a furnace full of wrong-sized billets. Physical Stop Without Delay: Exact length billets Shock free pushback Stop functions as pushback - fast cycle times Maximum Efficiency: Optional Integrated FusionBond® eliminates two-piece billets, reducing waste and increasing yields. Industry-leading chip collection system Enhanced Quality: Perfect square-cut Aluminum Log Saw …

More InfoFusionBond®

FusionBond® GRANCO CLARK FusionBond® reliably eliminates two-piece billets and the problems that can slow down your line, e.g., unusable profiles. The gaps and inconsistencies caused by alignment issues where the two pieces meet can be eliminated. Spot welding will not eliminate gaps and oxidation, and the welds often break during transport to the furnace. The FusionBond® produces a full-face stronger bond compared to multi-point welds. Significantly reduce scrap High recovery Truly no scrap from logs Eliminate press billet handling issues due to two-piece Remove cast-cut face oxidation No trapped air in container from bad cuts Elimination of two-piece billets Integrates with hot saw Pressure controlled rotation "Clean-up" cut before bonding Optional inert gas atmosphere Increased yield up to 4%

More InfoALUSPEED Taper Quench

Taper Quench Isothermal extrusion—maintaining a constant exit temperature over the entire extrusion cycle is the overriding benefit of the Billet Taper Quench. It allows maximum extrusion speed for a given alloy profile and press tonnage. It eliminates variations in dimension and structure along the length of the extruded product. Highest Quality Profiles: Reduced dimensional variation Maintain consistent extrusion temperature Eliminates end-of-extrusion blisters More Throughput: Taper heating allows faster press speeds Cycle time of less than 25 seconds Isothermal Extrusion: Lowest acquisition cost No induction heater The GRANCO CLARK Billet Taper Quench allows the press to run at the maximum speed allowed by the alloy, section geometry and press tonnage. Without the Taper Quench, container friction causes the billet to heat up during …

More InfoBillet Transfer

Billet Transfer GRANCO CLARK provides a choice of billet transfer mechanisms to meet a variety of requirements. Each transfer system is custom-engineered to match the press delivery point and avoid all potential interferences. Furnace-to-Press Billet Transfer Systems: Reliable billet transport from the heating system to the extrusion press Tray-Style Transfer Ideal for use with press loaders designed to receive a billet by pushing in from the rear but is adaptable to many arrangements. Ideal integration with a taper quench unit. Simple and reliable: The floor-mounted design is easily accessible for preventative maintenance (PM). Overhead-Style Transfer: Clear floor appearance: The overhead design allows better operator vision around the press area. Ideal for use in a multi-station arrangement where billets are moved …

More InfoExtrusion Processing

Granco Clark's automated profile-handling equipment sets a new standard in automation, delivering fully automated systems that achieve unparalleled throughput efficiency. Engineered with a focus on enhancing product surface quality, our equipment significantly minimizes labor costs, scrap production, and physical effort, all while reducing downtime.

Extrusion ProcessingExtrusion Processing

High Impact Velocity Quench

High Impact Velocity Quench GRANCO CLARK has been supplying “High Impact Velocity” quenches since 1985. We documented the underlying science two decades ago in a seminar paper at the Extrusion Technology Symposium in 2004 (ET-04). Cooling rate is determined by quench technology and profile thickness. For most crash box sections our systems can provide cooling rates of more than 200°F per second on enclosed hollows (that is - quenching only the outside of the profile). GRANCO CLARK's High Impact Velocity Quench provides the maximum heat transfer available in a profile quench. Unlike flood quenches, the High Impact Velocity Quench penetrates the steam barrier surrounding the profile and puts water droplets directly on the aluminum. More importantly, the GRANCO CLARK High Impact Velocity …

More InfoCooling

Air Quenching & Medium Cooling Systems Uniform, efficient cooling is essential for boosting profile quality, throughput and your bottom line. This is where GRANCO CLARK's experience in profile quenching stands above the rest. We have a 45 year history of design innovations in profile quenches. No other manufacturer can match that level of experience. We offer a variety of quenching and cooling systems, which accommodate a wide range of performance requirements and budget parameters. System Performance Consultation Available: Highest Cooling Rates Available Best Distortion Control in the Industry Rollover Water Wall Quench: Economical solution for achieving moderate heat transfer rates Integral Run-Out Cooling: Efficient air cooling in the extrusion run-out area Overhead Cooling Duct System: With an inside/outside air blend …

More InfoProfile Handling

Profile Handling Dents, scratches, chill marks. These are the consequences of outdated conveyors and walking beam systems that can damage profiles, increase scrap, and increase operating costs. Delivering a flawless product isn’t just a lofty goal, it’s what our customers deserve. That’s the biggest reason for investing in GRANCO CLARK's automated profile-handling equipment. With its superior degree of automation, our handling equipment will help you achieve maximum throughput. It will improve the overall surface quality of your product, reduce labor costs, scrap, physical effort and downtime. Your equipment is built to last, and to be serviced and repaired easily. Run-Out Conveyors:: Equipped to handle maximum extrusion speeds Integrated cooling Run-Out Transfer Systems:: A smooth transition from run-out to cooling Unique …

More InfoPullers

Single

Single Puller When space or budget constraints don’t allow for the use of our Double or Twin Pullers, GRANCO CLARK's Single Pullers can still improve your productivity. They produce even, twist-free profiles and reduce scrap about 3% over operation without a puller. Line efficiency is further enhanced when you combine our Single Puller with the GRANCO CLARK under-table Hot Extrusion Saw. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Puller applies just the right amount of tension as the profile emerges from the die Suitable for use with …

More InfoDouble

Double Puller The GRANCO CLARK Double Puller features two puller heads on the same track, allowing it to seek the weld mark and cut profiles on the fly. This allows it to meet short press dead-cycle times. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation No Stanchions Two puller heads on a single track AC drive motors with head-mounted brakes Ability to seek die weld mark cut profiles on the fly Multiple operational modes Laser position measurement Industrial Bluetooth (wireless) communications Continuous …

More InfoTwin

Twin Puller In addition to the Single and Double Puller, GRANCO CLARK offers Twin Pullers equipped with multiple operational programs. The Twin Puller includes two heads on separate tracks and an adjustable hot saw on a third track that cuts the profile during the dead cycle or on the fly. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Well-suited for use with double length systems Multiple operational modes Available with flying hot-saw Available with flying hot-saw Ability to cut on weld mark during dead cycle or on the …

More InfoTwin/Twin

Twin/Twin Puller On the GRANCO CLARK Twin/Twin Puller, both puller heads feature a saw. This allows the profile to be cut on the weld mark on the fly, as with a double puller, and no additional third head or saw is required. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Saws on each of the two puller heads Multiple operational modes Ability to cut on the weld mark on the fly, with no additional handover necessary or during dead cycle requirements Flexibility to select the sequence that best …

More InfoStretchers

Stretchers Stretching is one of the most critical post-quenching operations in the extrusion process. Performing that function correctly often makes the difference between usable product and scrap. An overstretched profile will be out of tolerance. A profile that is not stretched past its yield point will not be straight. Both are destined to become scrap. GRANCO CLARK Stretchers deliver precise, accurate stretching, which enhances profile quality and keeps scrap to a minimum. When used in conjunction with our belt systems, our Stretchers straighten and batch profiles for efficient downstream operations. GRANCO CLARK Stretchers accommodate a broad range of requirements. Our Stretchers are available in cam-style and controlled vertical crush jaw designs. No-man operational mode offers labor savings and give you …

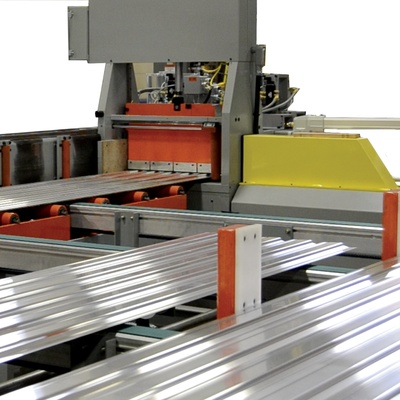

More InfoSaw & Gauge

Saw & Gauge Cutting large batches of extrusions is one of the keys to reaching high levels of productivity. Most existing Cut-off Saws have a limited width capacity, and are therefore inefficient and unproductive. GRANCO CLARK's Extrusion Cut-off Saws are large-capacity, high-quality, high-performance saws that provide extremely close tolerances and an excellent cut surface finish. They are durable with low maintenance, and designed with safety in mind. GRANCO CLARK's Extrusion Cut-off Saws provide superior cut tolerance, maximum throughput, and safe operation by means of a process that involves minimum manual intervention. Superior Cut Tolerance Advanced Automation: Servo-controlled gauge head positioning Safety: Floor mounted console or pedestal away from cutting area Electronically interlocked saw panels Substantial …

More InfoProfile Stacking

Profile Stacking System GRANCO CLARK Stacking System are cost-effective and efficient solution for off-loading cut profiles from the gauge table to aging racks. It improves operator safety, reduces labor costs, and minimizes the risk of profile marking. With automated stackers and spacer insertion, the system is easy to use and will help you save time and money. If you’re looking for a way to streamline your manufacturing process and improve your bottom line, consider investing in the GRANCO CLARK Stacking System. Major Savings: Quickly offload profiles from the gauge table Flexibility: Single or multiple end-to-end batch processing Automated oven rack loading/unloading Automated spacer insertion Single or multiple batch processing Reduced labor and injury-related costs through the elimination of manual …

More Info

Off-Line Equipment

Granco Clark Off-Line equipment means this equipment is not part of the initial extrusion line; rather, Granco Clark Off-Line equipment is placed in areas of final production

Off-Line EquipmentOff-Line Equipment

Saw Systems

Precision Saw

Precision Saw Industry’s Most Productive Saw: Exceptionally close tolerances combined with highest levels of productivity High speed plus large batch window Hitch feed provides maximum precision Tightest Tolerances Vertical and horizontal clamping on both sides of saw line for extremely precise cut Back gauge clamps product, providing the fastest indexing in the industry Unique hitch-feed mode prevents backrake, allowing for less additional machining and less scrap Batch-cuts any number of extrusions that can be contained in the 24 x 8 inch clamping window Back gauge lengths to meet any requirement Latches: safety interlocks instead of screw on machine guards for rapid blade change and maintenance Recipe setup for increased productivity Exceptionally close …

More InfoCold Billet Saw

Cold Billet Saw Eliminates Costly Scrap: Accurate billet lengths every time Compensation/Two-Piece Billet Cutting: Maximum usage of raw materials Square Cuts: Clean-cut, sharp-edge billets Rugged construction Fully enclosed saw blade Compensation/two-piece billet cutting Servo controlled measurement Integrated with loading and unloading tables Square cuts Longevity Dependability Increased safety for the operator Low noise level Maximum usage of raw materials Reduced complexity of the equipment, cutting down on maintenance requirements Provides the information for accurate cut lengths Complete sawing system designed for ease of use and precise control Delivers a clean-cut, sharp-edged billet

More InfoSample Cut Saw

Sample Cut Saw As the demand for high-quality extrusions rises, so does the need for samples of the process. Granco Clark offers a cost-effective and automated solution to meet this challenge. This saw is located in the cooling table between the runout and the stretcher. When integrated properly, the extrusion will be longer than normal by the desired scrap length. It will be automatically positioned so that it enters the sample saw. The remaining usable extrusion continues to the stretcher while the cut piece is handled as the customer requires. This could be an inspection table, short belt, drop bin, etc. The saw is comprised of a compact “up-cut” style blade feed, with integrated clamping and chip collection …

More InfoCold Log & Billet Processing

Cold Log and Billet Processing Cold Log and Billet Cutting, Stacking and Banding GRANCO CLARK Log and Billet Saw, Auto Bander and Robotic Stacker are game-changers for manufacturing companies that produce logs and billets. The system automates the entire process, from cutting the logs to stacking the billets and banding them for transport. With this system in place, manufacturers can increase their productivity, reduce their labor costs, and improve the overall efficiency of their operations. If you’re looking for a solution to streamline your log and billet cutting process, the Log and Billet Saw, Auto Bander and Robotic Stacker are worth considering. Rugged construction Fully enclosed saw blade …

More InfoOvens

Infrared Die Ovens

Infrared Die Ovens Controlled Temperature: Triple thermocouples (Air, Die, and Elements) to ensure dies are evenly heated Measured die temperature allows reheating warm dies Built To Last: Strong 3/16” (5mm) shell, stainless steel interior Die Temp Monitoring - No Die Damage Long Life Heaters with Over-temp Protection Customizable Configurations Heat the Die, Not the Air

More InfoDie Ovens

Die Ovens Leader in Heat Up TimesConvection Radiant and Hybrids Available Many Configurations Available Top/Front/Even Bottom Load Cool Skin Temperatures Chest-Type Model Rugged construction Well designed air-circulation system Top opening, hinged lid or sliding lid Longevity Low maintenance Space savings Multi-Compartment Model Multiple, individually heated drawers, each capable of holding several dies Easy access to all dies Top-quality construction Simultaneous heating of dies with different thermal requirements, increasing productivity Better thermal uniformity (less need to mix cold dies with hot dies) Reduced heat loss during die handling, which saves energy and increases temperature uniformity for better profile quality Increased safety Increased efficiency Durability No reaching required Infrared Model (see page 51, 52) Infrared Hybrid Convection …

More InfoAge & Anneal Ovens

Age & Anneal Ovens Single End Flow Age Oven: Simple, low-maintenance design delivers uniform temperatures Reversing End Flow Oven: Fast heat-up, excellent temperature uniformity Double End Flow Age Oven: Faster heat-up with higher temperature uniformity Side Flow Age Oven: Cross-flow circulation for highest thermal uniformity Continuous Aging Oven: Continuous production flow for highest throughput Rack Handling Systems: Minimum manpower requirements, maximum profile quality Excellent temperature uniformity—a nominal ±7° F (4º C) Quick heat-up of load (nominal one to two hours) Chamber sizes designed to meet your needs Charge and discharge transport systems, including rack stackers and rack destackers Available with multiple, pre-programmed age oven cycles …

More InfoAnodizing

Anodizing

Anodizing Expertise Fully Automated Anodizing GAZZANI ENGINEERING, leaders in process automation. Partnering with GAZZANI ENGINEERING to provide highly reliable equipment for automated handling systems and automation equipment for the aluminium anodizing plants. Fully automated cranes for anodizing, transferring systems and process controls are GAZZANI ENGINEERING speciality, to provide to customers the maximum performances, repeatability, quality and productivity. https://www.gazzanieng.com/anodizing/

More InfoAutomated Packaging Systems

Automated Packaging Systems

Automated Packaging Systems Customized Packing Configuration GAZZANI ENGINEERING will configure the proper layout for the profiles packaging based on requirements. GAZZANI ENGINEERING lines can work with different packing materials (stretch film, PE or paper) and reach configurable working speeds up to 48 meters/min. Adhesive tape machine for aluminium profiles PE Film Lamination Machine for Sheets Paper/PE sheet dispenser Various packaging lines solutions Bagging Machine - The Alternative Way https://www.gazzanieng.com/packaging-line/

More InfoMechanical Finishing Systems

Mechanical Finishing Systems

Mechanical Finishing Systems Eliminates Costly Scrap GAZZANI ENGINEERING Shot Blasting Machine. Shot blasting machine for mechanical matte finishing of aluminium profiles by stainless steel microspheres. Total elimination of surface defects and imperfections due to the extrusion process Drastic reduction of mud production during the anodizing process of aluminum, with a further decrease in the elimination cost of the wastage Substantial increase of production in the anodizing cycle of the profiles Removal of the natural oxidation hues on the extruded profiles, caused by atmosphere agents during a long-lasting storage of the profiles themselves before being treated (painted or anodized) https://www.gazzanieng.com/mechanical-finishing/

More InfoLaser

Exclusive technology only from Granco Clark and Laserax. Laser mark your extrusions and profiles for part traceability and identification in-line right at the press.

LaserLaser

Laser

Laser Mark Your Extrusions, Logs, and Billets Exclusive technology only from Granco Clark and Laserax Now you can laser mark your extrusions and profiles for part traceability and identification in-line right at the press. A quick unique part identifier (barcode, serial number) with a permanent and robust mark on the part surface directly within the fabrication process, without decreasing throughput. Laser marking offers the best contrasts to ensure perfect legibility The markings are resistant to aging, high temperatures, heavy salt spray testing, and intense UV exposure. High Contrast and Readable Barcodes Customizable HD Label Low Operational Costs Heat Resistant Laser Systems Shotblast Resistant Marking For more information, contact your Granco Clark Sales rep at 616-794-2600 or check out the LaserAx website at:https://www.laserax.com/applications/laser-marking-materials/metal

More Info

SCS Extrude

SCS Extrude is a powerful software system that orchestrates the extrusion process. It enables communication among individual machines while providing the office with real-time information.

SCS ExtrudeSCS Extrude

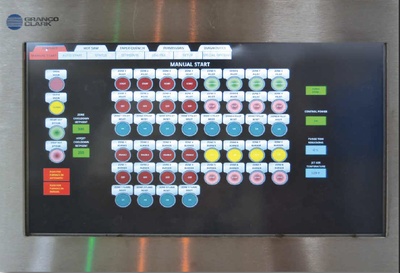

SCS Extrude

SCS Extrude First introduced in 1986, the GRANCO CLARK Supervisory Computer System (SCS) was developed to provide extruders with a completely integrated control system for automated extrusion lines. SCS Extrude is a powerful software system that orchestrates the extrusion process. It enables communication among individual machines, while providing the office with real-time information. It executes production schedules by automatically loading equipment parameters and recipes. It also tracks and diagnoses faults and then logs production and downtime data. Faster Changeover: - Load die change parameters without operator input Repeatable Setups: - Operating parameters can be precisely duplicated Automatic Reporting: - Tracks orders through your system and displays their status Fault Discovery/Correction: - Uncovers faults, diagnoses them, and displays recommendations to …

More InfoVideos and Literature

Access a comprehensive collection of equipment videos and literature designed to enhance your understanding and utilization of our cutting-edge equipment.

Videos and LiteratureVideos and Literature

Videos

Fly Through System Log Processing Log Washer Hot-Jet Billet & Log Furnace Hot Saw Fusionbond Log Shear Billet Transfer Taper Quench Extrusion Processing High Impact Velocity Quench Pass-Through Quench Cooling Pullers Profile handling Stretchers Saw & Gauge Profile Stacking Off-Line Equipment Cold Billet Saw Precision Saw Sample Cut Saw Cold Log & Billet Processing Ovens Age & Anneal Ovens Infrared Die Ovens Die Ovens

More InfoLiterature

Full Line Company Catalog Press Feedline Log Washer Hot-Jet Billet/Log Furnace Hot Billet Saw Fusionbond Taper Quench Billet Transfer Handling System High Impact Velocity Quench Cooling Pullers Profile Handling Stretcher Saw & Gauge Profile Stacking Ovens Age & Anneal Ovens IInfrared Die Ovens Die Ovens Saw Systems Cold Billet Saw Precision Saw

More Info