Stretchers

Stretchers

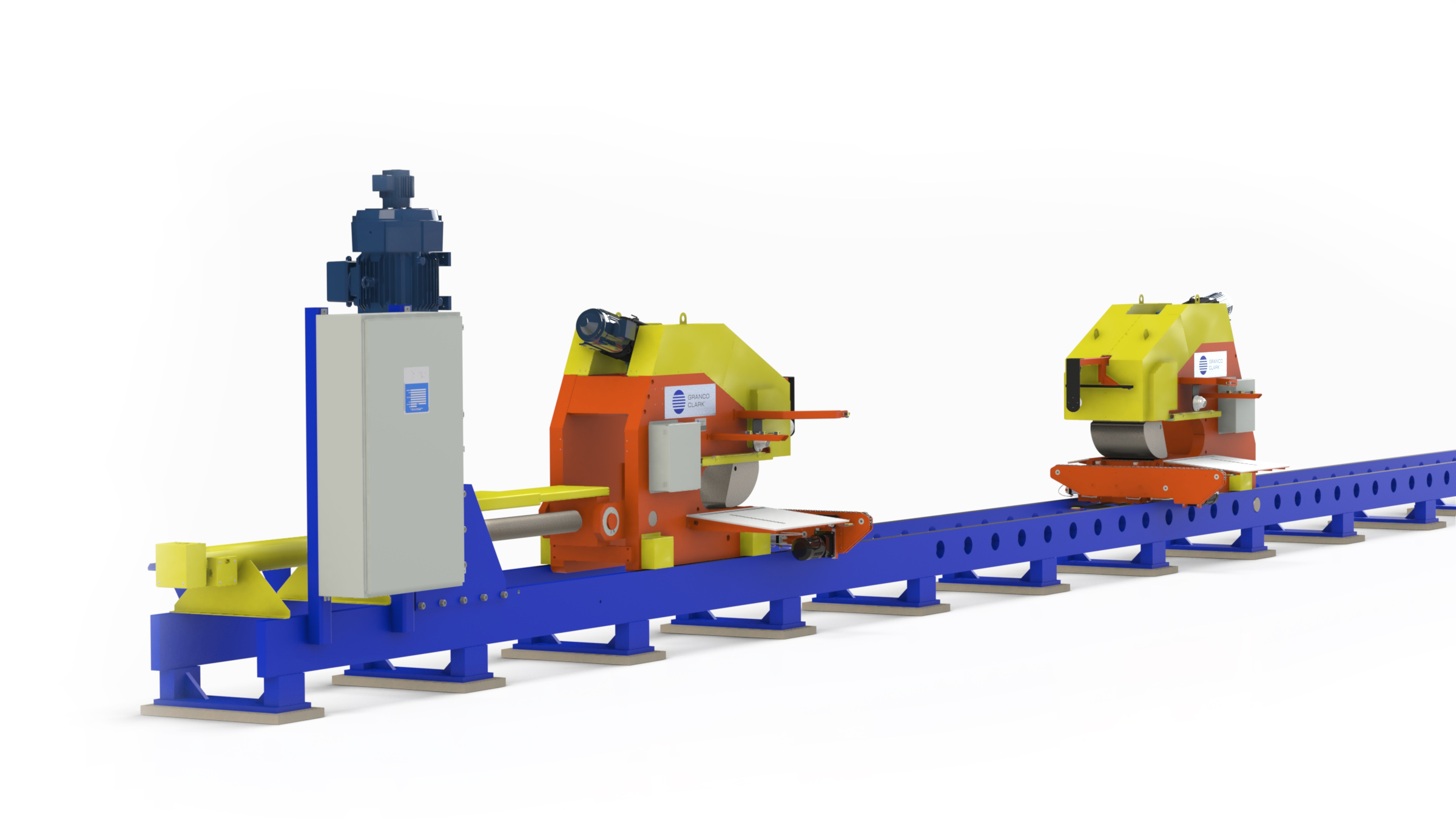

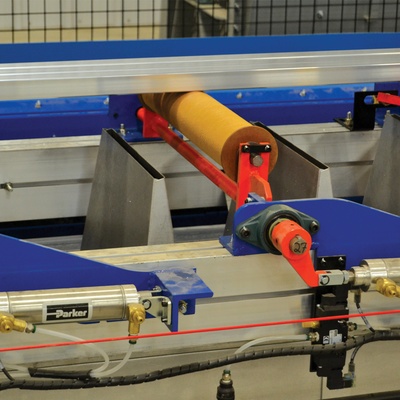

Stretching is one of the most critical post-quenching operations in the extrusion process. Performing that function correctly often makes the difference between usable product and scrap. An overstretched profile will be out of tolerance. A profile that is not stretched past its yield point will not be straight. Both are destined to become scrap.

GRANCO CLARK Stretchers deliver precise, accurate stretching, which enhances profile quality and keeps scrap to a minimum. When used in conjunction with our belt systems, our Stretchers straighten and batch profiles for efficient downstream operations.

GRANCO CLARK Stretchers accommodate a broad range of requirements. Our Stretchers are available in cam-style and controlled vertical crush jaw designs. No-man operational mode offers labor savings and give you the flexibility you need to meet operational challenges.

Cam Style:

- Ideal for accommodating a variety of profile shapes

Controlled Vertical Crush Stretcher:

- Maximum gripping with minimum distortion

- Efficient, accurate stretching

- State-of-the-art safety features, including safety mats, light curtains and two-handed safety controls

- Various jaw designs:—cam-style, diagonal “uni-slide,” controlled vertical crush

- One, two, or no-man operational modes

- Controlled crush distance and pressure (CVC model) Increased usable product

- Maximum operator safety

- Accommodate various operational needs

- Flexibility to meet varying operational challenges

- Preservation of profile surface quality and dimensional integrity

- Elimination of slippage

- Recipe Control:

- Stretch By Length

- Stretch By Percent

- Accurate Pre-Stretch Force Monitoring

Extrusion Processing

High Impact Velocity Quench

High Impact Velocity Quench GRANCO CLARK has been supplying “High Impact Velocity” quenches since 1985. We documented the underlying science two decades ago in a seminar paper at the Extrusion Technology Symposium in 2004 (ET-04). Cooling rate is determined by quench technology and profile thickness. For most crash box sections our systems can provide cooling rates of more than 200°F per second on enclosed hollows (that is - quenching only the outside of the profile). GRANCO CLARK's High Impact Velocity Quench provides the maximum heat transfer available in a profile quench. Unlike flood quenches, the High Impact Velocity Quench penetrates the steam barrier surrounding the profile and puts water droplets directly on the aluminum. More importantly, the GRANCO CLARK …

More InfoCooling

Air Quenching & Medium Cooling Systems Uniform, efficient cooling is essential for boosting profile quality, throughput and your bottom line. This is where GRANCO CLARK's experience in profile quenching stands above the rest. We have a 45 year history of design innovations in profile quenches. No other manufacturer can match that level of experience. We offer a variety of quenching and cooling systems, which accommodate a wide range of performance requirements and budget parameters. System Performance Consultation Available: Highest Cooling Rates Available Best Distortion Control in the Industry Rollover Water Wall Quench: Economical solution for achieving moderate heat transfer rates Integral Run-Out Cooling: Efficient air cooling in the extrusion run-out area …

More InfoProfile Handling

Profile Handling Dents, scratches, chill marks. These are the consequences of outdated conveyors and walking beam systems that can damage profiles, increase scrap, and increase operating costs. Delivering a flawless product isn’t just a lofty goal, it’s what our customers deserve. That’s the biggest reason for investing in GRANCO CLARK's automated profile-handling equipment. With its superior degree of automation, our handling equipment will help you achieve maximum throughput. It will improve the overall surface quality of your product, reduce labor costs, scrap, physical effort and downtime. Your equipment is built to last, and to be serviced and repaired easily. Run-Out Conveyors:: Equipped to handle maximum extrusion speeds Integrated cooling Run-Out Transfer Systems::

More InfoPullers

Single

Single Puller When space or budget constraints don’t allow for the use of our Double or Twin Pullers, GRANCO CLARK's Single Pullers can still improve your productivity. They produce even, twist-free profiles and reduce scrap about 3% over operation without a puller. Line efficiency is further enhanced when you combine our Single Puller with the GRANCO CLARK under-table Hot Extrusion Saw. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Puller applies just the right amount of tension as the profile emerges from the die Suitable for use with …

More InfoDouble

Double Puller The GRANCO CLARK Double Puller features two puller heads on the same track, allowing it to seek the weld mark and cut profiles on the fly. This allows it to meet short press dead-cycle times. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation No Stanchions Two puller heads on a single track AC drive motors with head-mounted brakes Ability to seek die weld mark cut profiles on the fly Multiple operational modes Laser position measurement Industrial Bluetooth (wireless) communications Continuous …

More InfoTwin

Twin Puller In addition to the Single and Double Puller, GRANCO CLARK offers Twin Pullers equipped with multiple operational programs. The Twin Puller includes two heads on separate tracks and an adjustable hot saw on a third track that cuts the profile during the dead cycle or on the fly. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Well-suited for use with double length systems Multiple operational modes Available with flying hot-saw Available with flying hot-saw Ability to cut on weld mark during dead cycle or on the …

More InfoTwin/Twin

Twin/Twin Puller On the GRANCO CLARK Twin/Twin Puller, both puller heads feature a saw. This allows the profile to be cut on the weld mark on the fly, as with a double puller, and no additional third head or saw is required. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Saws on each of the two puller heads Multiple operational modes Ability to cut on the weld mark on the fly, with no additional handover necessary or during dead cycle requirements Flexibility to select the sequence that best …

More InfoStretchers

Stretchers Stretching is one of the most critical post-quenching operations in the extrusion process. Performing that function correctly often makes the difference between usable product and scrap. An overstretched profile will be out of tolerance. A profile that is not stretched past its yield point will not be straight. Both are destined to become scrap. GRANCO CLARK Stretchers deliver precise, accurate stretching, which enhances profile quality and keeps scrap to a minimum. When used in conjunction with our belt systems, our Stretchers straighten and batch profiles for efficient downstream operations. GRANCO CLARK Stretchers accommodate a broad range of requirements. Our Stretchers are available in cam-style and controlled vertical crush jaw designs. No-man operational mode …

More InfoSaw & Gauge

Saw & Gauge Cutting large batches of extrusions is one of the keys to reaching high levels of productivity. Most existing Cut-off Saws have a limited width capacity, and are therefore inefficient and unproductive. GRANCO CLARK's Extrusion Cut-off Saws are large-capacity, high-quality, high-performance saws that provide extremely close tolerances and an excellent cut surface finish. They are durable with low maintenance, and designed with safety in mind. GRANCO CLARK's Extrusion Cut-off Saws provide superior cut tolerance, maximum throughput, and safe operation by means of a process that involves minimum manual intervention. Superior Cut Tolerance Advanced Automation: Servo-controlled gauge head positioning Safety: Floor mounted console or pedestal away …

More InfoProfile Stacking

Profile Stacking System GRANCO CLARK Stacking System are cost-effective and efficient solution for off-loading cut profiles from the gauge table to aging racks. It improves operator safety, reduces labor costs, and minimizes the risk of profile marking. With automated stackers and spacer insertion, the system is easy to use and will help you save time and money. If you’re looking for a way to streamline your manufacturing process and improve your bottom line, consider investing in the GRANCO CLARK Stacking System. Major Savings: Quickly offload profiles from the gauge table Flexibility: Single or multiple end-to-end batch processing Automated oven rack loading/unloading Automated spacer insertion Single or multiple batch …

More Info