Off-Line Equipment

Granco Clark Off-Line equipment means this equipment is not part of the initial extrusion line; rather, Granco Clark Off-Line equipment is placed in areas of final production

Saw SystemsSaw Systems

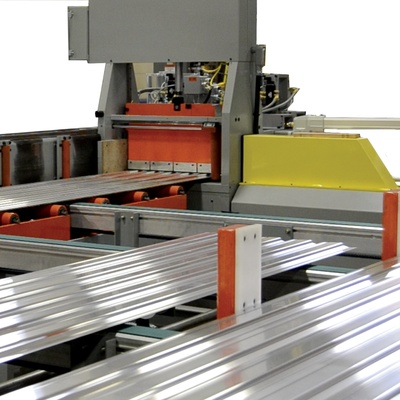

Precision Saw

Precision Saw Industry’s Most Productive Saw: Exceptionally close tolerances combined with highest levels of productivity High speed plus large batch window Hitch feed provides maximum precision Tightest Tolerances Vertical and horizontal clamping on both sides of saw line for extremely precise cut Back gauge clamps product, providing the fastest indexing in the industry Unique hitch-feed mode prevents backrake, allowing for less additional machining and less scrap Batch-cuts any number of extrusions that can be contained in the 24 x 8 inch clamping window Back gauge lengths to meet any requirement Latches: safety interlocks instead of screw on machine guards for rapid blade change and maintenance Recipe setup for increased productivity Exceptionally close tolerances: Cut length accuracy ±0.005 Straightness of cut ±0.002 …

More InfoCold Billet Saw

Cold Billet Saw Eliminates Costly Scrap: Accurate billet lengths every time Compensation/Two-Piece Billet Cutting: Maximum usage of raw materials Square Cuts: Clean-cut, sharp-edge billets Rugged construction Fully enclosed saw blade Compensation/two-piece billet cutting Servo controlled measurement Integrated with loading and unloading tables Square cuts Longevity Dependability Increased safety for the operator Low noise level Maximum usage of raw materials Reduced complexity of the equipment, cutting down on maintenance requirements Provides the information for accurate cut lengths Complete sawing system designed for ease of use and precise control Delivers a clean-cut, sharp-edged billet

More InfoSample Cut Saw

Sample Cut Saw As the demand for high-quality extrusions rises, so does the need for samples of the process. Granco Clark offers a cost-effective and automated solution to meet this challenge. This saw is located in the cooling table between the runout and the stretcher. When integrated properly, the extrusion will be longer than normal by the desired scrap length. It will be automatically positioned so that it enters the sample saw. The remaining usable extrusion continues to the stretcher while the cut piece is handled as the customer requires. This could be an inspection table, short belt, drop bin, etc. The saw is comprised of a compact “up-cut” style blade feed, with integrated clamping and chip collection for safety. …

More InfoCold Log & Billet Processing

Cold Log and Billet Processing Cold Log and Billet Cutting, Stacking and Banding GRANCO CLARK Log and Billet Saw, Auto Bander and Robotic Stacker are game-changers for manufacturing companies that produce logs and billets. The system automates the entire process, from cutting the logs to stacking the billets and banding them for transport. With this system in place, manufacturers can increase their productivity, reduce their labor costs, and improve the overall efficiency of their operations. If you’re looking for a solution to streamline your log and billet cutting process, the Log and Billet Saw, Auto Bander and Robotic Stacker are worth considering. Rugged construction Fully enclosed saw blade Compensation and two-piece billet cutting Servo controlled measurement Integrated with loading and unloading …

More Info

OvensOvens

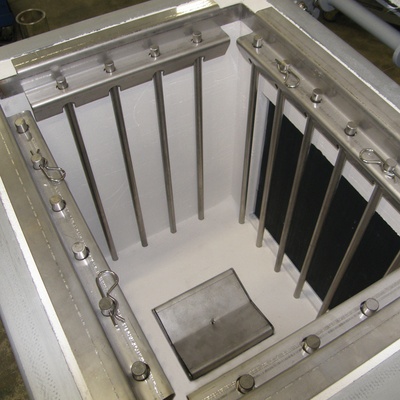

Infrared Die Ovens

Infrared Die Ovens Controlled Temperature: Triple thermocouples (Air, Die, and Elements) to ensure dies are evenly heated Measured die temperature allows reheating warm dies Built To Last: Strong 3/16” (5mm) shell, stainless steel interior Die Temp Monitoring - No Die Damage Long Life Heaters with Over-temp Protection Customizable Configurations Heat the Die, Not the Air

More InfoDie Ovens

Die Ovens Leader in Heat Up TimesConvection Radiant and Hybrids Available Many Configurations Available Top/Front/Even Bottom Load Cool Skin Temperatures Chest-Type Model Rugged construction Well designed air-circulation system Top opening, hinged lid or sliding lid Longevity Low maintenance Space savings Multi-Compartment Model Multiple, individually heated drawers, each capable of holding several dies Easy access to all dies Top-quality construction Simultaneous heating of dies with different thermal requirements, increasing productivity Better thermal uniformity (less need to mix cold dies with hot dies) Reduced heat loss during die handling, which saves energy and increases temperature uniformity for better profile quality Increased safety Increased efficiency Durability No reaching required Infrared Model (see page 51, 52) Infrared Hybrid Convection oven reliability with faster heat-up …

More InfoAge & Anneal Ovens

Age & Anneal Ovens Single End Flow Age Oven: Simple, low-maintenance design delivers uniform temperatures Reversing End Flow Oven: Fast heat-up, excellent temperature uniformity Double End Flow Age Oven: Faster heat-up with higher temperature uniformity Side Flow Age Oven: Cross-flow circulation for highest thermal uniformity Continuous Aging Oven: Continuous production flow for highest throughput Rack Handling Systems: Minimum manpower requirements, maximum profile quality Excellent temperature uniformity—a nominal ±7° F (4º C) Quick heat-up of load (nominal one to two hours) Chamber sizes designed to meet your needs Charge and discharge transport systems, including rack stackers and rack destackers Available with multiple, pre-programmed age oven cycles or operator adjustable cycles Uniform hardness for high product quality, minimal scrap Increased throughput Adaptable to …

More InfoAnodizingAnodizing

Anodizing

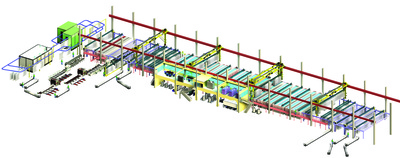

Anodizing Expertise Fully Automated Anodizing GAZZANI ENGINEERING, leaders in process automation. Partnering with GAZZANI ENGINEERING to provide highly reliable equipment for automated handling systems and automation equipment for the aluminium anodizing plants. Fully automated cranes for anodizing, transferring systems and process controls are GAZZANI ENGINEERING speciality, to provide to customers the maximum performances, repeatability, quality and productivity. https://www.gazzanieng.com/anodizing/

More InfoAutomated Packaging Systems

Automated Packaging Systems

Customized Packing Configuration

GAZZANI ENGINEERING will configure the proper layout for the profiles packaging based on requirements. GAZZANI ENGINEERING lines can work with different packing materials (stretch film, PE or paper) and reach configurable working speeds up to 48 meters/min.

- Adhesive tape machine for aluminium profiles

- PE Film Lamination Machine for Sheets

- Paper/PE sheet dispenser

- Various packaging lines solutions

- Bagging Machine - The Alternative Way

Automated Packaging SystemsAutomated Packaging Systems

Automated Packaging Systems

Automated Packaging Systems Customized Packing Configuration GAZZANI ENGINEERING will configure the proper layout for the profiles packaging based on requirements. GAZZANI ENGINEERING lines can work with different packing materials (stretch film, PE or paper) and reach configurable working speeds up to 48 meters/min. Adhesive tape machine for aluminium profiles PE Film Lamination Machine for Sheets Paper/PE sheet dispenser Various packaging lines solutions Bagging Machine - The Alternative Way https://www.gazzanieng.com/packaging-line/

More Info

Mechanical Finishing Systems

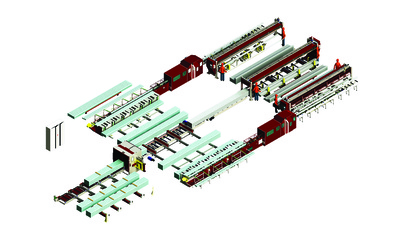

Mechanical Finishing Systems

Eliminates Costly Scrap

GAZZANI ENGINEERING Shot Blasting Machine.

- Shot blasting machine for mechanical matte finishing of aluminium profiles by stainless steel microspheres.

- Total elimination of surface defects and imperfections due to the extrusion process

- Drastic reduction of mud production during the anodizing process of the aluminum, with further decrease of the elimination cost of the wastage

- Substantial increase of production in the anodizing cycle of the profiles

- Removal of the natural oxidation hues on the extruded profiles, caused by atmosphere agents during a long-lasting storage of the profiles themselves before being treated (painted or anodized)

Mechanical Finishing SystemsMechanical Finishing Systems

Mechanical Finishing Systems

Mechanical Finishing Systems Eliminates Costly Scrap GAZZANI ENGINEERING Shot Blasting Machine. Shot blasting machine for mechanical matte finishing of aluminium profiles by stainless steel microspheres. Total elimination of surface defects and imperfections due to the extrusion process Drastic reduction of mud production during the anodizing process of aluminum, with a further decrease in the elimination cost of the wastage Substantial increase of production in the anodizing cycle of the profiles Removal of the natural oxidation hues on the extruded profiles, caused by atmosphere agents during a long-lasting storage of the profiles themselves before being treated (painted or anodized) https://www.gazzanieng.com/mechanical-finishing/

More Info