Die Ovens

Die Ovens

- Leader in Heat Up TimesConvection

- Radiant and Hybrids Available

- Many Configurations Available Top/Front/Even Bottom Load

- Cool Skin Temperatures

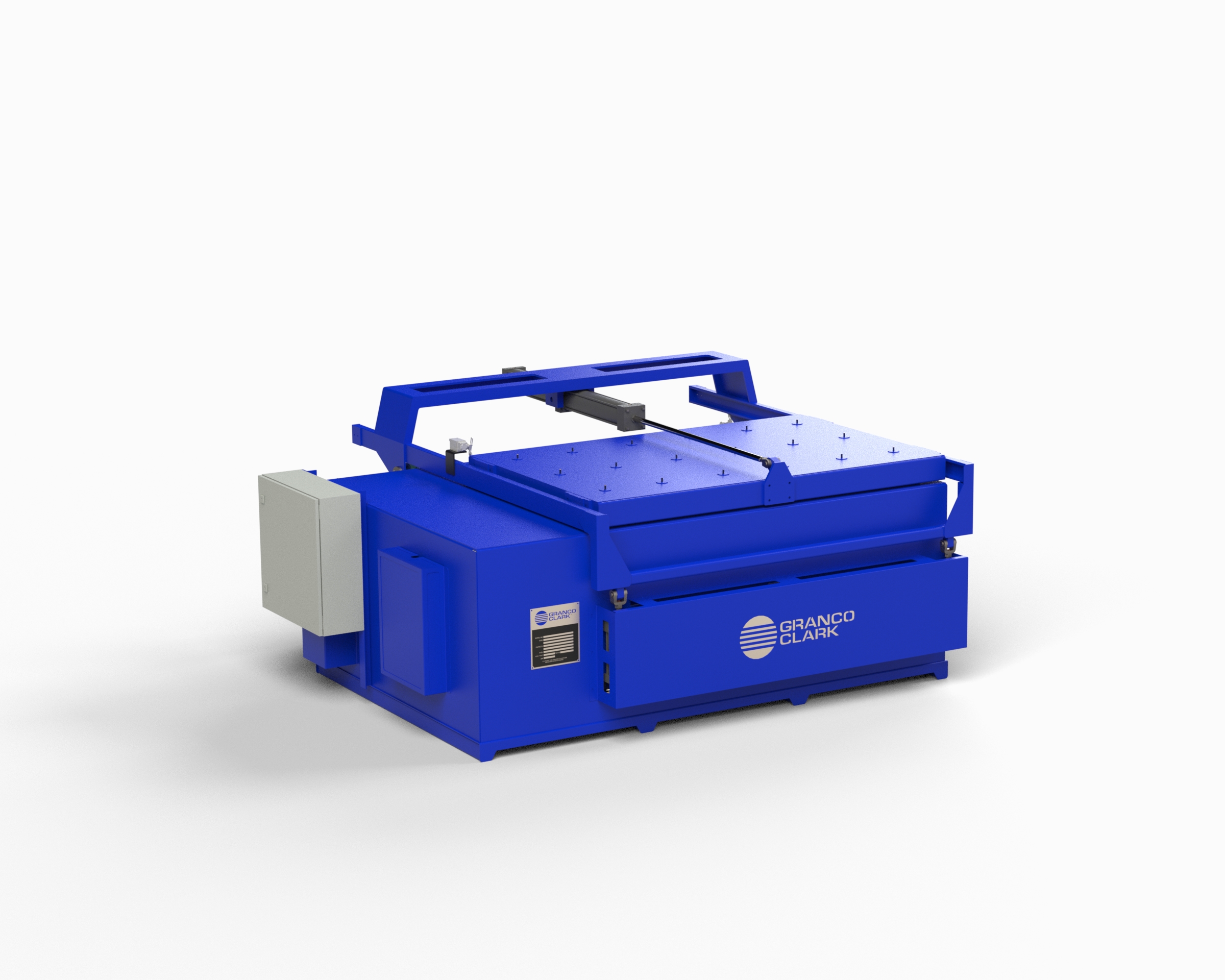

- Chest-Type Model

- Rugged construction

- Well designed air-circulation system

- Top opening, hinged lid or sliding lid

- Longevity

- Low maintenance

- Space savings

- Multi-Compartment Model

- Multiple, individually heated drawers, each capable of holding several dies

- Easy access to all dies

- Top-quality construction

- Simultaneous heating of dies with different thermal requirements, increasing productivity

- Better thermal uniformity (less need to mix cold dies with hot dies)

- Reduced heat loss during die handling, which saves energy and increases temperature uniformity for better profile quality

- Increased safety

- Increased efficiency

- Durability

- No reaching required

- Infrared Model (see page 51, 52)

- Infrared Hybrid

- Convection oven reliability with faster heat-up times

- Top-loading and front-loading designs are available

- Less thermal stress

- Excellent for large die sizes

Ovens

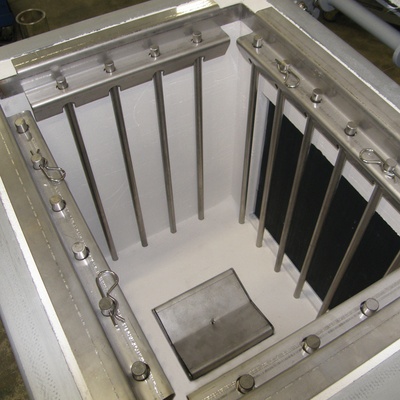

Infrared Die Ovens

Infrared Die Ovens Controlled Temperature: Triple thermocouples (Air, Die, and Elements) to ensure dies are evenly heated Measured die temperature allows reheating warm dies Built To Last: Strong 3/16” (5mm) shell, stainless steel interior Die Temp Monitoring - No Die Damage Long Life Heaters with Over-temp Protection Customizable Configurations Heat the Die, Not the Air

More InfoDie Ovens

Die Ovens Leader in Heat Up TimesConvection Radiant and Hybrids Available Many Configurations Available Top/Front/Even Bottom Load Cool Skin Temperatures Chest-Type Model Rugged construction Well designed air-circulation system Top opening, hinged lid or sliding lid Longevity Low maintenance Space savings Multi-Compartment Model Multiple, individually heated drawers, each capable of holding several dies Easy access to all dies Top-quality construction Simultaneous heating of dies with different thermal requirements, increasing productivity Better thermal uniformity (less need to mix cold dies with hot dies) Reduced heat loss during die handling, which saves energy and increases temperature uniformity for better profile quality Increased safety Increased efficiency Durability No reaching required Infrared Model (see page 51, 52) Infrared Hybrid Convection …

More InfoAge & Anneal Ovens

Age & Anneal Ovens Single End Flow Age Oven: Simple, low-maintenance design delivers uniform temperatures Reversing End Flow Oven: Fast heat-up, excellent temperature uniformity Double End Flow Age Oven: Faster heat-up with higher temperature uniformity Side Flow Age Oven: Cross-flow circulation for highest thermal uniformity Continuous Aging Oven: Continuous production flow for highest throughput Rack Handling Systems: Minimum manpower requirements, maximum profile quality Excellent temperature uniformity—a nominal ±7° F (4º C) Quick heat-up of load (nominal one to two hours) Chamber sizes designed to meet your needs Charge and discharge transport systems, including rack stackers and rack destackers Available with multiple, pre-programmed age oven cycles …

More Info