Double

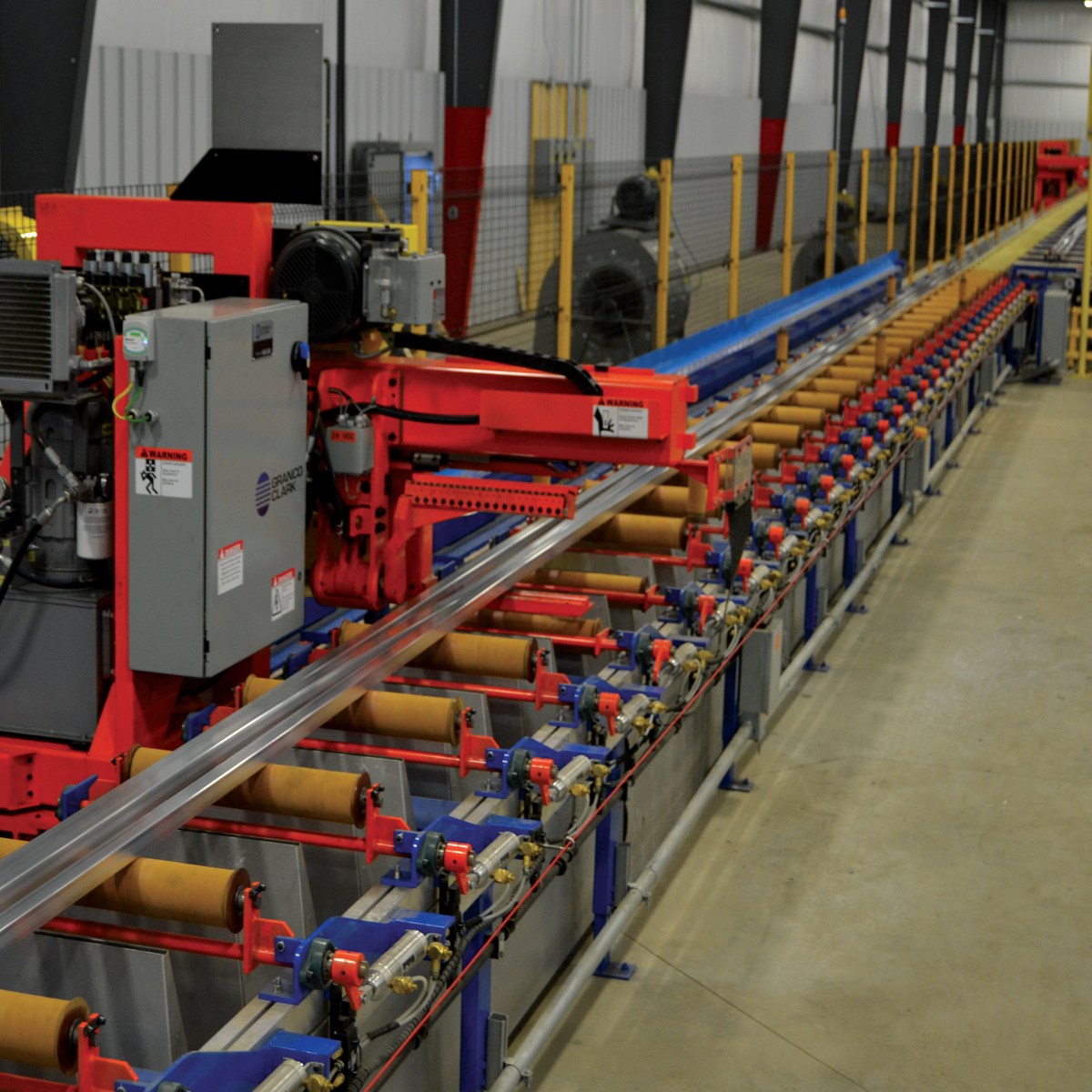

Double Puller

The GRANCO CLARK Double Puller features two puller heads on the same track, allowing it to seek the weld mark and cut profiles on the fly. This allows it to meet short press dead-cycle times.

- Excellent Chip Collection

- Drop Away Rollers - No Lifting

- Simplest Design – Low Maintenance

- No Marking

- No Foundation Work

- Best Install Time

- Nine Modes of Operation

- No Stanchions

- Two puller heads on a single track

- AC drive motors with head-mounted brakes

- Ability to seek die weld mark cut profiles on the fly

- Multiple operational modes

- Laser position measurement

- Industrial Bluetooth (wireless) communications

- Continuous production

- Highly efficient use of space Increased production

- Ability to meet short press, dead-cycle times 2–3% less scrap than single puller and up to 6% over operation without a puller

- Flexibility, selection of sequence that best meets your needs

- Fast identification of faults - Built-in diagnostics and predictive maintenance messages

- Increased effectiveness of the compensation-cut program on furnace/shear installations, reducing butt scrap - Ability to use longer billets

Pullers

Single

Single Puller When space or budget constraints don’t allow for the use of our Double or Twin Pullers, GRANCO CLARK's Single Pullers can still improve your productivity. They produce even, twist-free profiles and reduce scrap about 3% over operation without a puller. Line efficiency is further enhanced when you combine our Single Puller with the GRANCO CLARK under-table Hot Extrusion Saw. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Puller applies just the right amount of tension as the profile emerges from the die Suitable for use with …

More InfoDouble

Double Puller The GRANCO CLARK Double Puller features two puller heads on the same track, allowing it to seek the weld mark and cut profiles on the fly. This allows it to meet short press dead-cycle times. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation No Stanchions Two puller heads on a single track AC drive motors with head-mounted brakes Ability to seek die weld mark cut profiles on the fly Multiple operational modes Laser position measurement Industrial Bluetooth (wireless) communications Continuous …

More InfoTwin

Twin Puller In addition to the Single and Double Puller, GRANCO CLARK offers Twin Pullers equipped with multiple operational programs. The Twin Puller includes two heads on separate tracks and an adjustable hot saw on a third track that cuts the profile during the dead cycle or on the fly. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Well-suited for use with double length systems Multiple operational modes Available with flying hot-saw Available with flying hot-saw Ability to cut on weld mark during dead cycle or on the …

More InfoTwin/Twin

Twin/Twin Puller On the GRANCO CLARK Twin/Twin Puller, both puller heads feature a saw. This allows the profile to be cut on the weld mark on the fly, as with a double puller, and no additional third head or saw is required. Excellent Chip Collection Drop Away Rollers - No Lifting Simplest Design – Low Maintenance No Marking No Foundation Work Best Install Time Nine Modes of Operation Saws on each of the two puller heads Multiple operational modes Ability to cut on the weld mark on the fly, with no additional handover necessary or during dead cycle requirements Flexibility to select the sequence that best …

More Info